Structural Analysis

6th Edition

ISBN: 9781337630931

Author: KASSIMALI, Aslam.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

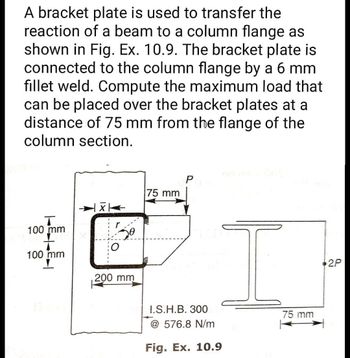

Transcribed Image Text:A bracket plate is used to transfer the

reaction of a beam to a column flange as

shown in Fig. Ex. 10.9. The bracket plate is

connected to the column flange by a 6 mm

fillet weld. Compute the maximum load that

can be placed over the bracket plates at a

distance of 75 mm from the flange of the

column section.

P

75 mm

X

T

100 mm

F

100 mm

2P

200 mm

I.S.H.B. 300

@576.8 N/m

Fig. Ex. 10.9

75 mm

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps with 2 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, civil-engineering and related others by exploring similar questions and additional content below.Similar questions

- Problem 4.81 The 60-mm-diameter cylinder is made from Am 1004- T61 magnesium and is placed in the clamp when the temperature is T₁ = 20° C. (Figure 1) Figure 1 of 1 -11 100 mm 150 mm Part A If the 304-stainless-steel carriage bolts of the clamp each have a diameter of 9 mm, and they hold the cylinder snug with negligible force against the rigid jaws, determine the force in the cylinder when the temperature rises to T2 = 130°C. Express your answer to three significant figures and include the appropriate units. F= Submit HA Value Units My Answers Give Up ? Provide Feedback Continuearrow_forwardA C130x10 tension member is welded to a plate as shown in the figure. The channel is of Grade 350W steel. The channel is welded on both sides with 110 mm long fillet weld. Assume the weld does not govern the capacity, calculate the factored tension resistance of the channel. The tension resistance is not governed by the plate. C130 XI0arrow_forwardTwo steel plates, each 400mm wide and 12mm thick, are to be joined together by a lap splice (single). The electrode to be used for the weld has a nominal tensile strength of 550Mpa. Determine the following:a. the maximum weld size that can be usedb. effective net area of the fillet weld using the maximum weld size allowed by the manualc. the maximum load that can be resisted by the weld using the maximum weld size allowed by the manual.arrow_forward

- Using SMAW process, E70 electrodes and an A572 steel. Determine the length of the side fillet welds for the full capacity the 125x100x10mm angle tension member as shown below. Assume that the member is subjected to repeated stress variations making any connection eccentricity undesirable. Check the block shear strength of the member. Assume that the WT chord has sufficient strength to develop the weld strengths and the thickness of its web is 12mm. Use U=0.87 for class use and LRFD Method only. L125x100x10 V WT BOTTOM CHORD (please solve completely and neatly thank you so much) 12Sarrow_forwardA0.375-in.-diameter steel [E = 30,000 ksi] bolt (1) is placed in a copper tube (2), as shown. The copper [E = 16,000 ksi] tube has an outside diameter of 1.000 in., a wall thickness of 0.12 in., and a length of L= 7.0 in. Rigid washers, each with a thickness of t= 0.125 in., cap the ends of the copper tube. The bolt has 24 threads per inch. This means that each time the nut is turned one complete revolution, the nut advances 1/24 in. The nut is hand-tightened on the bolt until the bolt, nut, washers, and tube are just snug, meaning that all slack has been removed from the assembly, but no stress has yet been induced. What stresses are produced in the bolt and in the tube if the nut is tightened an additional quarter turn past the snug-tight condition? Rigid washer Rigid washer Bolt () Tube (2) If the force induced in the bolt by advancing the nut is F1, and force induced in the tube by advancing the nut is F2, what is the relationship between F1 and F2?arrow_forwardSee the image. Two steel plates are welded together. The thickness of the bottom plate is 10mm and the thickness of the top plate is 8mm. What is the maximum and minimum sizes of the weld.arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Structural Analysis (10th Edition)Civil EngineeringISBN:9780134610672Author:Russell C. HibbelerPublisher:PEARSON

Structural Analysis (10th Edition)Civil EngineeringISBN:9780134610672Author:Russell C. HibbelerPublisher:PEARSON Principles of Foundation Engineering (MindTap Cou...Civil EngineeringISBN:9781337705028Author:Braja M. Das, Nagaratnam SivakuganPublisher:Cengage Learning

Principles of Foundation Engineering (MindTap Cou...Civil EngineeringISBN:9781337705028Author:Braja M. Das, Nagaratnam SivakuganPublisher:Cengage Learning Fundamentals of Structural AnalysisCivil EngineeringISBN:9780073398006Author:Kenneth M. Leet Emeritus, Chia-Ming Uang, Joel LanningPublisher:McGraw-Hill Education

Fundamentals of Structural AnalysisCivil EngineeringISBN:9780073398006Author:Kenneth M. Leet Emeritus, Chia-Ming Uang, Joel LanningPublisher:McGraw-Hill Education

Traffic and Highway EngineeringCivil EngineeringISBN:9781305156241Author:Garber, Nicholas J.Publisher:Cengage Learning

Traffic and Highway EngineeringCivil EngineeringISBN:9781305156241Author:Garber, Nicholas J.Publisher:Cengage Learning

Structural Analysis (10th Edition)

Civil Engineering

ISBN:9780134610672

Author:Russell C. Hibbeler

Publisher:PEARSON

Principles of Foundation Engineering (MindTap Cou...

Civil Engineering

ISBN:9781337705028

Author:Braja M. Das, Nagaratnam Sivakugan

Publisher:Cengage Learning

Fundamentals of Structural Analysis

Civil Engineering

ISBN:9780073398006

Author:Kenneth M. Leet Emeritus, Chia-Ming Uang, Joel Lanning

Publisher:McGraw-Hill Education

Traffic and Highway Engineering

Civil Engineering

ISBN:9781305156241

Author:Garber, Nicholas J.

Publisher:Cengage Learning