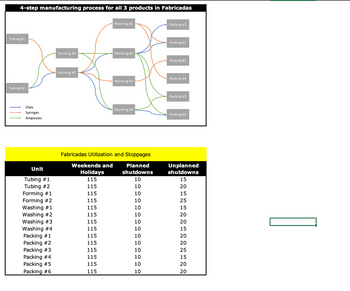

1- Assume all planned shutdowns and unplanned shutdowns are zero and find the Utilization or Implied Utilization of each station. It is your choice if you want to find U of IU. This part has 3 points out of 10 points.

2- Assume ONLY the unplanned shutdowns are zero and find the Utilization or Implied Utilization of each station (It is your choice if you want to find U of IU). In other words for this part, planned shut downs are what provided to you in the Excel file. It is important how you plan them. Based on your plan, you will get different U or IU. This part has 3 points out of 10 points.

3- Now, let's relax the assumption that unplanned shutdowns are zero. In other words, all planned and unplanned shutdowns are what provided to you in the question. Hint: For this part, you need some knowledge from some other OTM courses. Why? Because we have UNPLANNED SHUTDOWNS. You don't know when they are going to happen. Find the Utilization or Implied Utilization of each station. It is your choice if you want to find U of IU. This part has 2 points out of 10 points.

![A

B

1

2

Demand Projections Q3 2020 (actual)

3456789

Ampoules

Vials

Syringes

Product

10

11

Ampoules

12

Vials

13

Syringes

14

15

5

10

C

Demand History and Projections

Product-wise cycle time

D

E

F

G

Q4 2020

Q1 2021

Q2 2021

[in lots]

55

20

35

60

65

30

35

40

45

Cycle Time (hours)

60

63

57

665

Cycle time breakup by product and line

15

16

Cycle Time (hours/process)

17

18

19

20

Ampoules

Vials

Syringes

Net lot equivalent rejected in a quarter

21

Product

22

23

Ampoules

24

Vials

25

Syringes

26

27

28

29

30

31

32

33

34

35

36

37

Tubing

6

9

6

Hot-forming

Washing

Packing

12

18

9

21

9

18

222

24

24

24

Bend tubing Rejects Contamination rejects

Glass breakages

Air bubbles

1

5.7

3.5

2.8

2.8

3.4

6

3.2

3

5.2

2.8

2.6

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

Table of Content

Data Exhibit-1

Data Exhibit-2

Data Exhibit-3

Data Exhibit-4](https://content.bartleby.com/qna-images/question/afb35d62-6245-40da-b5d2-74fad3e6ad86/62ed3836-189d-4f8c-9bb4-f99af802c22f/qfsip8_thumbnail.png)

Step by stepSolved in 2 steps

- A single server queuing system with a Poisson arrival rate and exponential service time has an average arrival rate of 9 customers per hour and an average service rate of 13 customers per hour. The probability of 6 customers in the system is : a. 0.9661 b. 0.8899 c. 0.3077 d. 0.03388arrow_forwardConsider the table attached below:Assuming an M/M/1 setup, a service rate of 18 customers every 10 minutes, and a traffic intensity of 0.90.Assume a probability density function characterized by the exponential distribution.i). Compute the corresponding variates.ii). How robust is the above derived density function?arrow_forwardFour trucks, 1, 2, 3, and 4, are waiting on a loading dock at XYZ Company that hasonly a single service bay. The trucks are labeled in the order that they arrived at thedock. Assume the current time is 1:00 P.M. The times required to unload each truck and the times that the goods they contain are due in the plant are given in thefollowing table.Truck Unloading Time (minutes) Time Material Is Due1 20 1:25 P.M.2 14 1:45 P.M.3 35 1:50 P.M.4 10 1:30 P.M.Determine the schedules that result for each of the rules FCFS, SPT, EDD, andCR. In each case compute the mean flow time, average tardiness, and number oftardy jobs.arrow_forward

- Consider doctor’s office: Physician’s have 30 min appointment slots starting at 8 AM to 6 PM Physicians spend 90 min (1.5 hrs.) each day on electronic medical records and 30 min on claims processing/questions related to medical insurance Typically, physicians have 75 percent appointments booked in advance, which leads to frequent cancellations. One out of 6 patients do not show up Even though appointment slots are 30 min, physicians spend on average 23 minutes with patient. Out of those 23 min, say 5 min could be done by nurse How much of physician’s work is value addedarrow_forwardAn ice cream truck is parked at a local beach and customers queue up to buy ice creams at a rate of one per minute. The arrival pattern of people buying ice cream is essentially random. It takes 40 seconds on average to serve a customer ice cream, with a standard deviation of 20 seconds. Find the following expected measures of performance for this system: the expected time in the queue for ice cream, the expected total time to get an ice cream, and the expected number of customers waiting for ice cream.arrow_forwardplease dont answer in image format. Do type Thnksarrow_forward

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.