Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Question

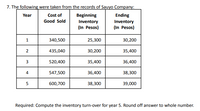

Transcribed Image Text:7. The following were taken from the records of Sauyo Company:

Year

Cost of

Beginning

Ending

Good Sold

Inventory

Inventory

(In Pesos)

(In Pesos)

340,500

25,300

30,200

2.

435,040

30,200

35,400

520,400

35,400

36,400

4

547,500

36,400

38,300

600,700

38,300

39,000

Required: Compute the inventory turn-over for year 5. Round off answer to whole number.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps with 2 images

Knowledge Booster

Similar questions

- 2.7 Which of the following help explain how the Reorder Point (ROP) works in conjunction with the Economic Order Quantity (Q), the number of orders (N) and the time between orders (T)? a) The Economic Order Quantity (Q) and the Annual Demand (D) are used to determine the number of Order (N) b) The number of orders (N) and the number of days that a firm works (W) are used to determine the time span between orders (T) c) Orders are placed every T days unless the inventory on hand fall to or below the Reorder Point d) Only a and b e) f) Only b and c All of a, b and c 2.8 The objective of Inventory Management is to balance inventory investment (cost) and customer service. a) TRUE b) False 2.9 The Economic Order Quantity (EOQ), the number of orders, the Reorder Point (ROP), the time between orders are important analytics in Inventory Management. a) TRUE b) FALSE 2.10 The number of working days for a firm is an important input in calculating the components of the Economic Order Quantity…arrow_forward16. Cheryl Hunter is responsible for maintaining adequate hospital supplies atfictional St. Thomas Hospital. The demand and lead times for syringes are assumedto be constant. During the past year, the daily demand for syringes was 80 units, andthe lead time from the supplier was 4 days. What is the reorder point?arrow_forwardInventory turns ProofSmart Inc., a supplier of home insulation materials, was burned down in a recent fire. From the remains of what used to be the accounting ledger, the following information was recovered: Inventory Gross Margin Inventory Turns Multiple Choice 2011 $2,367321 16% 13 Prior to the fire, ProofSmart saw a sales growth of 15% in 2012, a record performance for the 18 year-old company. What was the sales for 2012? NOTE: Gross margin is defined as 1-(COGS /Sales). 30772573 36492036 67369882 2012 $2,418,257 45% (unreadable) 42106226arrow_forward

- question #2 Same problem statement: Weekly demand for DVD-Rs at a retailer is normally distributed with a mean of 1,000 boxes and a standard deviation of 150. Currently, the store places orders to the supplier, with a reorder point of 4,200 boxes. The order quantity to the supplier is fixed at 5,000 boxes. Replenishment lead time is 4 weeks, fixed order cost per order is $100, each box costs the retailer $10, and the inventory holding cost is 25% per year. If the retailer wants to achieve a 99% service level (use the z-value with one decimal, as in Table 13.4 on page 400 of the textbook), what should be the safety stock value? Numeric Response 772.8 SHARE f5 f6 4- f7 ♫+ fg fil W f12. insert prt sc delete home @ 0 end 1:23 PM 11/15/2022 pg Larrow_forwardQ2) Clancy's Motors has the following demand to meet for custom manufactured fuel injector parts. The holding cost for that item is $2 per month and each setup costs $80. Lead time is 0 months. Calculate the planned order releases using: (a) the EOQ technique, and (b) the POQ technique. And What are the costs of each plan, including the holding cost of any inventory left over after month 7? What technique performance is better. Month 1 2 3 4 5 6 7 Requirement 400 150 200 150 100 150 250 Answer: (a) The monthly holding cost = $2/month Average monthly demand = ??? units The EOQ = ??? units Total inventory held = ??? units Setup costs = $??? Holding cost = $???? Total cost = $???? (b) POQ Interval = ?.??, round to # month. Total inventory held = ? units Setup costs = $??? Holding cost = $? Total cost = $???arrow_forwardquestion #5 Same problem statement: Weekly demand for DVD-Rs at a retailer is normally distributed with a mean of 1,000 boxes and a standard deviation of 150. Currently, the store places orders to the supplier, with a reorder point of 4,200 boxes. The order quantity to the supplier is fixed at 5,000 boxes. Replenishment lead time is 4 weeks, fixed order cost per order is $100, each box costs the retailer $10, and the inventory holding cost is 25% per year. Under the current order quantity of 5,000 boxes and current reorder point of 4,200 boxes, what would be the order-up-to level S that the retailer should use as a baseline to calculate how much inventory to order when conducting a periodic review? Numeric Response 1500 f4 ***** LA f5 40 % f6 4- 0 C + & 7 < Prev. 門 fg KAA * 8 5 of 5 DII hp f10 DDI 9 Next fi W f12. insert prt sc + 11 ( ← delete backspace home num lock end 1:24 PM 11/15/2022 pg uparrow_forward

- Problem 13-16 The McDonald's fast-food restaurant on campus sells an average of 4,800 quarter-pound hamburgers each week. Hamburger patties are resupplied twice a week, and on average the store has 465 pounds of hamburger in stock. Assume that the hamburger patties cost $3 a pound and there are 52 weeks in a year. a. What is the inventory turnover for the hamburger patties? (Round your answer to 2 decimal places.) Inventory turnover per year b. On average, how many days of supply are on hand? (Do not round intermediate calculations. Round your answer to 2 decimal places.) Average days of supplyarrow_forwardQ 12.30: Alvin's Apple Orchard manages inventory closely to maintain freshness. In the past four years, its current assets have fluctuated with demand and supply of fresh fruits. The following table reproduces selected balance sheet items: 2020 2019 2018 2017 Accounts 10.1% 11.9% 12.1% 12.4% receivable Raw material 7.0% 7.6% 7.8% 8.0% inventory Finished goods 5.2% inventory 4.6% 5.3% 5.4% Alvin's common size analysis shows that A inventory management improved over the period as a result of better control over raw material inventory. В inventory management deteriorated over the five years as a result of poor control over finished raw material inventory. C receivables are becoming easier to collect. inventory management improved over the period as a result of better control over finished goods inventory. Darrow_forwardTOPIC : Inventory Systems for Independent Demandarrow_forward

- Need in Detail (No AI)arrow_forwardQuestion: What level of safety stock should be maintained? Please show the solution. Thank youarrow_forwardGenchev Industries conducts an ABC analysis of its inventory and develops the following table from its findings. Item Annual Usage Unit Cost Dollar Usage 1 9,960 $43.20 $430,272 2 3,362 $22.80 $76,654 3 8,332 $9.90 $82,487 4 3,074 $22.30 $68,550 5 2,968 $8.40 $24,931 6 4,195 $25.00 $104,875 7 4,536 $19.20 $87,091 8 9,538 $65.60 $625,693 9 3,484 $3.20 $11,149 10 10,232 $5.70 $58,322 Which of these items is a C item? a. Item 8 b. Item 6 c. Item 5 d. Item 1arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.