Principles of Heat Transfer (Activate Learning with these NEW titles from Engineering!)

8th Edition

ISBN: 9781305387102

Author: Kreith, Frank; Manglik, Raj M.

Publisher: Cengage Learning

expand_more

expand_more

format_list_bulleted

Question

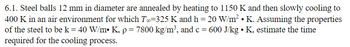

Transcribed Image Text:6.1. Steel balls 12 mm in diameter are annealed by heating to 1150 K and then slowly cooling to

400 K in an air environment for which T∞=325 K and h = 20 W/m² • K. Assuming the properties

of the steel to be k = 40 W/m• K, p = 7800 kg/m³, and c = 600 J/kg • K, estimate the time

required for the cooling process.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps

Knowledge Booster

Similar questions

- A 0.6-cm diameter mild steel rod at 38C is suddenly immersed in a liquid at 93C with hc=110W/m2K. Determine the time required for the rod to warm to 88C.arrow_forward6. a. The heat flux applied to the walls of the biomass combustion furnace is 20 W/m2. The furnace walls have a thickness of 10 mm and a thermal conductivity of 12 W/m.K. If the wall surface temperature is measured to be 50oC on the left and 30oC on the right, prove that conduction heat transfer occurs at a steady state!b. Heating the iron cylinder on the bottom side is done by placing the iron on the hotplate. This iron has a length of 20 cm. The surface temperature of the hotplate is set at 300oC while the top side of the iron is in contact with the still outside air. To reach the desired hotplate temperature, it takes 5 minutes. Then it takes 15 minutes to measure the temperature of the upper side of the iron cylinder at 300oC. Show 3 proofs that heat transfer occurs transientlyarrow_forwardanswer provided is correctarrow_forward

- - A 40 x 40 cm copper slab # mm thick at a uniform temperature of 250 °C suddenly has its surface temperature lowered 30 °C. Find the time at which the slab temperature becomes 90°C ; p=9000 ke/m’, c=0.38 KJ/kgK, k=370 W/mK and h=00 W/m’K. 2arrow_forward5.52 Steel is sequentially heated and cooled (annealed) to relieve stresses and to make it less brittle. Consider a 100-mm-thick plate (k = 45 W/m.K, p = 7800 kg/m³, Cp c, = 500 J/kg .K) that is initially at a uniform tempera- ture of 300°C and is heated (on both sides) in a gas-fired furnace for which T = 700°C and h = 500 W/m² K. How long will it take for a minimum temperature of 550°C to be reached in the plate?arrow_forwardSuppose that the 10 cm thick concrete wall of a commercial building measures 30 mby 4 m. The energy impinging on the surface is 700 Wm-2. Under these conditionsthe external air temperature is 25ºC, and the internal and external surfacetemperatures of the concrete wall are 17ºC and 40ºC, respectively.(a) State and briefly describe the three heat transfer mechanisms.[30%](b) Calculate the net amount of thermal energy radiated by the wall.[40%](c) State your assumptions and briefly discuss their effect on the relativesizes of the heat transfer mechanisms.[30%]Data for Question A3.Heat transfer coefficient of air at 25ºC = 5 Wm-2K-1Thermal conductivity of concrete = 1.2 Wm-1K-1Emissivity of concrete = 0.85Stefan’s constant = 5.7 x 10-8 Wm-2K-4arrow_forward

- I need the answer as soon as possiblearrow_forward3.4 Estimate the rate of heat loss due to radiation from a covered pot of water at 95 ° C. How does this compare with the 60 W that is lost due only to convection and conduction losses? What amount of energy input would be needed to maintain the water at its boiling point for 30 minutes? The polished stainless steel pot is cylindrical, 20 cm in diameter and 14 cm high, with a tight-fitting flat cover. The air temperature in the kitchen is about 25 ° C. State any assumptions you make in deriving your estimatesarrow_forward2-1. Temperature Response in Cooling a Wire. A small copper wire with a diameter of 0.792 mm and initially at 366.5 K is suddenly immersed in a liquid held constant at 311 K. The convection coefficient h 85.2 W/m K. The physical properties can be assumed constant and are k =374 W/m K, c, = 0.389 kJ/kg K, and p = 8890 kg/m2. (a) Determine the time in seconds for the average temperature of the wire to drop to 338.8 K (one-half the initial temperature difference). (b) Do the same but for h 11.36 W/m2 K (c) For part (b), calculate the total amount of heat removed for a wire 1.0 m р u (A long. (a) t 5.66 s Ans. the Smou hire is lons asbume Nhere rraolius , here radlius yinder hitu x Chapter 14 Principles of Unsteady-State Heat Transferarrow_forward

- Example: . A steel ball [c-0.46 kJ/kg C, k-35 W/m. C] 5.0 cm in diameter and initially at a uniform temperature of 450°C is suddenly placed in a controlled environment in which the temperature is maintained at 100°C. The convection heat-transfer coefficient is 10 W/m². C. Calculate the time required for the ball to attain a temperature of 150°C. Solution: We anticipate that the lumped-capacity method will apply because of the low value of h and high value of k.We can check by using Equation (3.9): hLc B₁ = k 3 Lc = T 0.025 =-= = 0.00833 A₂ 4mr² 3 3 hle 10-0.00833 B₁ = = = 0.0023 < 0.1 k 35 The lumped system capacitance method is valid and can used. Therefore, may can use equation 3.4: t= pvc In 0₁ hAs 0 92 HEAT TRANSFER t = pvc In pvc Ti-Too hAs T-Too T = 150 °C, p = 7800 kg/m³. Too-100 °C, h=10 w/m².C. T₁-450 °C, c-460 J/kg. "C. pvc In Ti-Too t = hAs T-Too t= Pr³c In Ti-Too h4r² T-T t= 1 In Ti-To pre 3h T-T V -= = 7800+0.025-460 In 3.10 450-100 150-100 = 5818.3 s= 1.62 h 6arrow_forwardSteel balls 12 mm in diameter are annealed by heating to 1100 K and then slowly cooling to 360 K in an air environment for which T. = 325 Kand h = 20 W/m2-K. Assuming the properties of the steel to be k = 40 W/m-K,p = 7800 kg/m, and c = 600 J/kg-K, estimate the time required for the cooling process. The time required for the cooling process isi h.arrow_forward4-A spherical interplanetary probe of 0.5 m diameter contains electronics thatdissipate 150 W. If the probe surface has an emissivity of 0.8 and the probe does not receive radiation from other surfaces, as, for example from the sun, what is the probe surface temperature?arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Principles of Heat Transfer (Activate Learning wi...Mechanical EngineeringISBN:9781305387102Author:Kreith, Frank; Manglik, Raj M.Publisher:Cengage Learning

Principles of Heat Transfer (Activate Learning wi...Mechanical EngineeringISBN:9781305387102Author:Kreith, Frank; Manglik, Raj M.Publisher:Cengage Learning

Principles of Heat Transfer (Activate Learning wi...

Mechanical Engineering

ISBN:9781305387102

Author:Kreith, Frank; Manglik, Raj M.

Publisher:Cengage Learning