Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

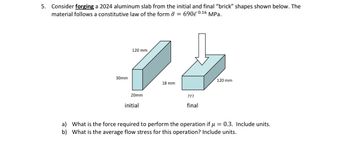

Transcribed Image Text:5. Consider forging a 2024 aluminum slab from the initial and final "brick" shapes shown below. The

material follows a constitutive law of the form σ = 690€ 0.16 MPa.

30mm

120 mm

18 mm

120 mm

20mm

initial

???

final

a) What is the force required to perform the operation if μ=0.3. Include units.

b) What is the average flow stress for this operation? Include units.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 4 steps with 3 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- How do i solve this question?: a) Find the normal stress due to bending caused by V. The answer should be in MPa to 2 decimal places. b) Find the shear stress caused by T. The answer should be in MPa to 2 decimal places. c) Apply the maximum-Distortion-Energy Theory and calculate Mises equivalent stress. The answer should be in MPa to 2 decimal places.arrow_forward2. A rectangular piece of jello is subjected to simple shear as shown in Fig. 2. (a) Using the expressions for the linear strain tensor, compute the value of the shear strain €12. (b) From €12, calculate the engineering shear strain 12. (c) Compute the average engineering shear strain 712 using the definition of engineer- ing shear strain and compare it with the 12 calculated in (b). A X₂ 150 mm B 3 mm 200 mm 3 mm X₁ Figure 2: A rectangular piece of jello being sheared.arrow_forwardFor some metal alloy, the following engineering stresses produce the corresponding engineering plastic strains prior to necking. On the basis of this information, what engineering stress (in MPa) is necessary to produce an engineering plastic strain of 0.250? Engineering stress (MPa) Engineering strain 217 232 0.176 0.301arrow_forward

- A bar of a steel alloy is subjected to a tensile load; the specimen is 370 mm long and of square cross section 5.3 mm on a side.a) If the stress is 1250 MPa, compute the magnitude of the load necessary to produce an elongation of 2.22mm. b) What will be the deformation after the load has been released?arrow_forwardPlease don't provide handwritten solution .....arrow_forwardDon't use chat gpt It Chatgpt means downvotearrow_forward

- Please don't provide handwritten solution ......arrow_forward#5arrow_forwarda) Calculate the reaction forces in terms of F andtheta.b) Calculate the internal shear force and moment as a function of x using cuts and summingforces and moments in terms of F, L, andtheta.c) Calculate the shear force and moments by integration in terms of x, L, F andtheta.d) Assuming a rectangular cross section compute the average normal stress for the case F =10kNat 30° where b =0.04 m, h = 0.08 m, at the point x = L/4, L = 1 m at the centroid.e) With the cross section given above compute the average normal stress for the case F =10kN at30° at the point x = L/4, L = 1 m at each surface of the beam.f) Calculate the shear stress at the top and bottom surface, at the neutral axis and at x = 0.25 mand y = 0.02 m above the neutral axis.arrow_forward

- 2. A 10 mm diameter cylindrical specimen of an aluminium alloy is loaded in uniaxial tension in a testing machine. a) If the specimen begins to yield at a load of 30 kN, what is the yield stress of the material? b) At the point where yielding begins, the measured increase in length between two points initially 50 mm apart is 0.27 mm. At what strain does yielding occur? c) If the load-deflection curve is linear up to the yield point, what is the elastic modulus of the material? d) If the diameter of the specimen was reduced by 18 um at the yield point, what is the Poisson's ratio of the material? [ans.: (a) 382 MPa; (b) 5.4E-3; (c) 70.7 GPa; (d) 0.333]arrow_forwarda) Calculate the maximum and average stresses un sections A and B, take t= 0.45inarrow_forwardBig and clear handwriting with all the steps. Make sure calculations and answers are accurate please. THANK YOUarrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY