Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN: 9781259696527

Author: J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher: McGraw-Hill Education

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

solve c) & d)

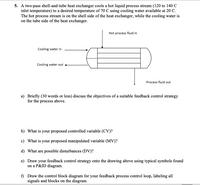

Transcribed Image Text:5. A two-pass shell-and-tube heat exchanger cools a hot liquid process stream (120 to 140 C

inlet temperature) to a desired temperature of 70 C using cooling water available at 20 C.

The hot process stream is on the shell side of the heat exchanger, while the cooling water is

on the tube side of the heat exchanger.

Hot process fluid in

Cooling water in

Cooling water out

Process fluid out

a) Briefly (30 words or less) discuss the objectives of a suitable feedback control strategy

for the process above.

b) What is your proposed controlled variable (CV)?

c) What is your proposed manipulated variable (MV)?

d) What are possible disturbances (DV)?

e) Draw your feedback control strategy onto the drawing above using typical symbols found

on a P&ID diagram.

f) Draw the control block diagram for your feedback process control loop, labeling all

signals and blocks on the diagram.

Expert Solution

arrow_forward

Step 1

Given:

Process fluid in at 120 to 140

Process fluid out at 70

Cooling water available at 20

Below is the heat exchanger with temperature control system:

Step by stepSolved in 3 steps with 1 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, chemical-engineering and related others by exploring similar questions and additional content below.Similar questions

- Q2/A) The system is shown in the next page: 1. Find the value of (m) when the damping ratio () is (0.7). Then obtain the maximum over shoot, peak time, rise time, and settling time. 2. Determine (on) and (C) when (m) equal zero. 3. Calculate the value of steady state error for this system if the input is a unit ramp. X(s) 250 Y(s) S(S+10) 3m S + 1arrow_forwardF1 F2 A2 P2 The following is known: Area, A1= 0.3 ft and A2= 7.6 A1- Assuming an incompressible fluid If a force F1 of 44.3 lbf / ft2 is applied at (1) then the resultant force, F2 in Ibf is equal to -- ?arrow_forwardexcel spreadsheetarrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY

Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Introduction to Chemical Engineering Thermodynami...

Chemical Engineering

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind...

Chemical Engineering

ISBN:9781118431221

Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:WILEY

Elements of Chemical Reaction Engineering (5th Ed...

Chemical Engineering

ISBN:9780133887518

Author:H. Scott Fogler

Publisher:Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:9781285061238

Author:Lokensgard, Erik

Publisher:Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:9780072848236

Author:Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:McGraw-Hill Companies, The