Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

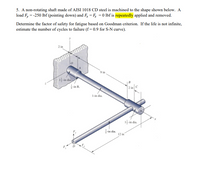

Transcribed Image Text:5. A non-rotating shaft made of AISI 1018 CD steel is machined to the shape shown below. A

load Fy = -250 lbf (pointing down) and F, = F, = 0 lbf is repeatedly applied and removed.

Determine the factor of safety for fatigue based on Goodman criterion. If the life is not infinite,

estimate the number of cycles to failure (f = 0.9 for S-N curve).

2 in

9 in

1-in dia.

B

-in R.

2 in

1-in dia.

1글-in dia.

-in din.

12 in

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps with 2 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- Find the diameter of a shaft made of (37 Mn 2 steel) having the ultimate tensile strength as (600 MPa) and yield stress as (440 MPa). The shaft is subjected to completely reversed axial load of (200 kN). Neglect stress concentration factor and assume surface finish factor as (0.8). The factor of safety may be taken as (1.5). (After the diameter was found, correct it for the actual size factor). mechanical design pls solve fastarrow_forwardProblem 2: Let FA=100 N and F= 208.33 N for the shaft below. The bearings D and B act as pin supports. The shaft is made of 2014 aluminum alloy with a yield strength of 276 MPa. The shaft has a diameter of 8 mm. Based on the maximum shear stress (MSS) theory, determine if the shaft is safe. Determine the corresponding safety factor. Y 45 mm 30 mm D. 20 mm FC 20° Gear 1 50-mm dia. Shaft FA 20° Gear 2 24-mm dia.arrow_forwardThe shaft is shown in Figure 3 is modified using the shaft from Question 2. Manufacturer selected as machined surface treatment for the shaft. It contains two fillets and one groove. The shaft rotates at 3000 řpm, whilst the imposed loads remain static. (a) Ifthe shaft is subjected to two-point load as shown below, F =10 kN, Calculate the factor of safety with respect to fatigue failure. (b) If the shaft is subjected to two-point load F= 10 kN while transmitting a power of P = 32 kW, Calculate the factor of safety with respect to fatigue failure. (L1 = 70 mm, L2 = 100 mm, L3 = 80 mm, La = 40 mm, Ls = 50 mm, L6 = 30 mm, Rj = 2 mm, R2 1 mm, R3= 4 mm, d = 24mm and D = 32mm,) 0.3F 0.7F LI Ls L. L6 ノ R1 R3 R2arrow_forward

- The shaft shown in the figure is machined from AISI 1030 CD steel. The shaft rotates at a constant RPM and is supported by roller bearings at A and B. The profile keyway at F has static stress concentration factor of Ktb = 2.312 for bending. The applied forces at gears C, D and F are in the same plane as the bearing reactions and remain constant. a) b) Clearly draw and label shear and bending diagrams for the shaft. Determine the factor of safety against bending fatigue only at location F (centerline of Gear F) assuming 50% reliability and state in words if the shaft will have infinite life based on this location. T 1.500 1.25 Ø- BEARING 1.160 A E 4.5 0.375 & GEAR C 500 lbf C -1.75 Ø 3.0 & GEAR F 300 lbf FV -0.75 2.5 BEARING -0.50 0.0312 R- B 2.5 3/8 x 3/8 PROFILE KEYWAY -0.375 GEAR D 1.5625 KEYWAY DETAIL AT "F" 450 lbf D 1/4 x 1/4 PROFILE KEYWAY -1.25 Øarrow_forward7-3 The section of shaft shown in the figure is to be designed to approximate relative sizes of d = 0.75D and r = D/20 with diameter d conforming to that of standard rolling- bearing bore sizes. The shaft is to be made of SAE 2340 steel, heat-treated to obtain minimum strengths in the shoulder area of 175 kpsi ultimate tensile strength and 160 kpsi yield strength with a Brinell hardness not less than 370. At the shoulder the shaft is subjected to a completely reversed bending moment of 600 lbf • in, accompaniced by a steady torsion of 400 lbf · in. Use a design factor of 2.5 and size the shaft for an infinite life using the DE-Goodman criterion. Problem 7-3 Section of a shaft containing a grinding-relief groove. Unless otherwise specified, the diameter at the root of the groove d, =d - 2r, and though the section of diameter d is ground, the root of the groove is still a machined surface.arrow_forwardFigure below shows a rotating shaft simply supported in ball bearings at A and D and loaded by a nonrotating orce Fof 6.8 kN. Using ASTM "minimum" strengths, estimate the life of the part. 6T td7 (a) Shaft drawing showing all dimensions in millimeters; all fillets 3-mm radius. The shaft rotates and the load is stationary; material is machined from AISI 1050 cold-drawn steel. (b) Bending moment diagram.arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY