Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

Transcribed Image Text:46. A garden hose is used as a siphon to drain a pool, as shown in Figure P2.46.

The garden hose has a 3/4-in. inside diameter (ID). Assuming no friction,

calculate the flow rate of water through the hose if the hose is 25 ft long.

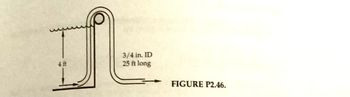

Transcribed Image Text:3/4 in. ID

25 ft long

FIGURE P2.46.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps with 1 images

Knowledge Booster

Similar questions

- Water enters a fountain through a pipe with a cross-sectional area A₁ at a flowrate Q. The pressure in the inlet pipe is p₁. The water then leaves through a nozzle with a cross- sectional area A₂ and at an angle 0, as shown in Figure Q5. Both the inlet and the nozzle are at a height h₂, and the jet reaches a maximum height h3. You may assume that viscosity is negligible. a) Find the horizontal force on the block b) What is the horizontal-component (u₂), vertical component (v₂) and magnitude (V₂) of the velocity of the jet as it leaves the nozzle? c) What is the maximum height of the jet? You may assume that the horiztonal component of velocity is the same at every point in the jet. P₁ A₂. Ө h₂ h3 Figure Q5: Jet emitting from a fountain.arrow_forwardFor a pumper truck pumping water to a fire, the back pressure is the additional pressure on the pump caused by the height of the nozzle. (Another way of thinking of back pressure is as the minimum pressure the pumper must produce in order to make water flow out the end of the nozzle.) Consider a pumper at street level pumping water through a hose to firefighters on the top of the ninth floor of a building. If each floor is 16 feet high, what is the head of water at the mouth of the nozzle?arrow_forward4.4 A tank containing water is placed on a trolley, which is attached to the wall by a cable, as shown in Fig. 4.28. A pipe bend is connected to the tank through which a jet of water is coming out with a velocity of 7.5m/s. If the diameter of the nozzle is 40 mm, calculate the tension in the cable. 7.5 m/s 30% Fig. 4.28 [Ans: 61.215 N]arrow_forward

- The plunger diameter of a single acting reciprocating pump is 115 mm and the stroke is 230 mm. The suction pipe is 90 mm in diameter and 4.2 m long. If cavitation takes place at the suction head of 4 m, the barometer stands at 10,3 m of water, and the water level in the sump is 3 m below the pump cylinder axis. 2.1 Find the maximum allowable speed to operate the pump 2.2 What power is expected in overcoming friction at this speed, take f=0.01arrow_forwardProblem 2. A garden hose with an attached nozzle is used to fill a container with water. The nozzle starts at a diameter of 2 cm and is then reduced to 0.8 cm at the exit. In 50 seconds, the nozzle and hose are able to fill the container with 10 gallons of water. Find the volumetric flow rate (m³/s), the mass flow rate (kg/s), and the average velocity (m/s) at the at the nozzle exit. Assume the density p of water is 1000 kg/m³.arrow_forward1. A propeller 2 f t in diameter moves at 20 f t/s in water and produces a thrust of 1000 lbf . Find the ratio of the upstream to downstream velocities, and the efficiency. 2. An airplane flies at 140 mph at sea level at 60◦F. The propeller diameter is 8 f t, and the slipstream has a velocity of 200 mph relative to the airplane. Find: (a) The propeller efficiency. (b) The flow velocity in the plane of the propeller. (c) The power input. (d) The thrust of the propeller. (e) The pressure difference across the propeller disk.arrow_forward

- A groundwater well with produces 80 m/hr. and has a hydraulic conductivity of 20 m/d. Calculate the following: a. The length of the screen b. The diameter of the delivery pipe. c. The velocity head and the friction losses in the delivery pipe. d. What is the required power of the pump if the abstraction efficiency was 70%? Assume the following: The percentage of the opening in the screen is 17%, the entrance velocity is 1.55 cm/sec, the diameter of the screen is 30 cm, water velocity in the tube is 2.2 m/sec. Assume any missing data.arrow_forwardRefer to Fig. X5.2.2. Assume a = I m, b = 4 m, and the flow to be frictionless in the siphon. Find the rate of discharge in m'ls and the pressure head at B if the pipe has a uniform diameter of 150 mm.arrow_forwardPumps: A centrifugal pump having 4 stages in parallel, delivers 18 kiloliters/min of liquid against a head of 25 m. The diameter of the impellers being 24 cm and the speed of 1800 rpm. A pump is to be made up with a number of stages in series of similar construction to that of the first pump to run at 1250 rpm and to deliver 15 kiloliters/min against a totalhead of 250 m. Find the diameter of the impellers and the number of stages required in this case. Answer: D = 46.63 cm, n = 6 stagesarrow_forward

- In car service station water flows through a vertical pipe reduced from a pipe of diameter D to another diameter 0.5 D. The flow velocity at the inlet to the contraction is 2 m/s and pressure is 20N/cm2 if the height of the contraction measures 2m, what is the pressure at the exit of the contraction? Draw diagram neatly.arrow_forwardB1.A hydraulic pump delivers 12.5 litres per minute towards pressure of 225 bar Find the following (a) Calculate the hydraulic power in kW (b) If the overall efficiency of the pump is given as 67% .Find the input of electric power needed tỏ drive the pump in wattsarrow_forwardSection 5.1.4 Deforming Control Volume 5.30 (WILEY A hypodermic syringe (see Fig. P5.30) is used to apply a vaccine. If the plunger is moved forward at the steady rate of 20 mm/s and if vaccine leaks past the plunger at 0.1 of the volume flowrate out the needle opening, calculate the average velocity of the needle exit flow. The inside diameters of the syringe and the needle are 20 mm and 0.7 mm. Qleak Qout Figure P5.30arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY