Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

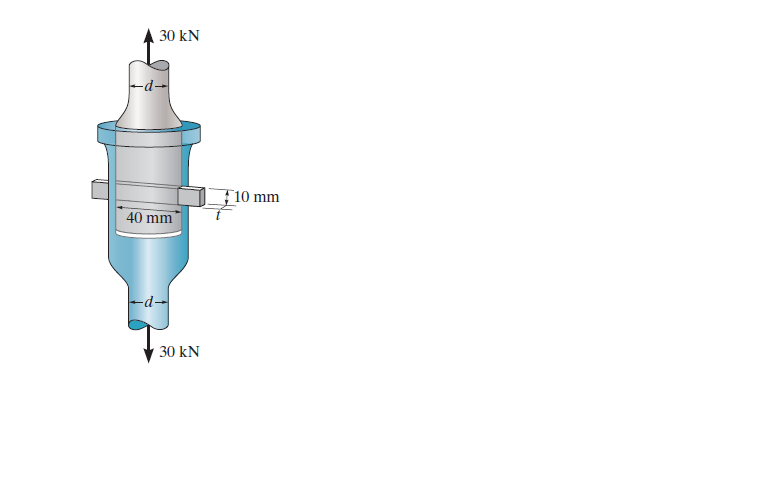

The cotter is used to hold the two rods together. Determine the smallest thickness t of the cotter and the smallest diameter d of the rods. All parts are made of steel for which the failure of normal stress is sfail = 500 MPa and the failure shear stress is tfail = 375 MPa. Use a factor of safety of (F.S.)t = 2.50 in tension and (F.S.)s = 1.75 in shear.

Transcribed Image Text:30 kN

710 mm

40 mm

30 kN

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 5 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- Two solid cylindrical rods (1) and (2) are joined together at flange B and loaded as shown. If F₁ = 13 kips, F₂ = 34 kips, and the normal stress in each rod must be limited to 22 ksi, determine the minimum diameter d₁ required for rod (1). A (2) d₁ F₂ B C O 1.087 in. O 0.823 in. O 0.541 in. O 0.867 in. O 1.003 in. d₂arrow_forwardTwo wood members of uniform cross section are joined using a simple glued scarf splice. Determine the normal and shearing stresses in the glued splice. The column is loaded in tension through the centroid with the load indicated. 2.4 kip 6" 60° 2.4 kiparrow_forwardThe five-bolt connection shown must support an applied load of P = 235 kN. If the average shear stress in the bolts must be limited to 195 MPa, determine the minimum bolt diameter that may be used in the connection. Answer:d = i mm.arrow_forward

- Part A -80 mm- P 75 mm -40 mm 30 mm If the bolt head and the supporting bracket are made of the same material having a failure shear stress of Tfail = 150 MPa, determine the maximum allowable force P that can be applied to the bolt so that it does not pull through the support. Apply a factor of safety of F.S. = 2.5 against shear failure. Express your answer to three significant figures and include the appropriate units.arrow_forwardFor a lap joint, determine the maximum safe load P which may be applied if the shearing stress in the rivets is limited to 60 MPa, the bearing stress in the plates to 110 MPa, and the average tensile stress in the plate to 140 MPaarrow_forwardFBD 3. Determine the required thickness of member BC and the diameter of the pins at A and B if the failure normal stress for member BC is Ofail = 30 ksi, and the failure shear stress for the pins is Tfail = 12 ksi. Use a safety factor of 1.2 to your design. Solution: 1.5 in. 60° 8 ft 5 kip/ftarrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY