Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

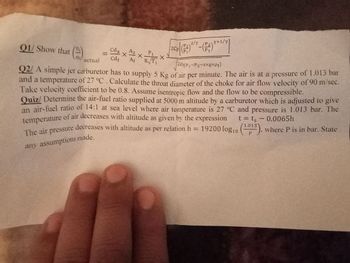

Transcribed Image Text:2/Y

Y+1

2Cp

Q1/ Show that

Cda

Az x

P1

mactual

Cdf

Af

R/T₁

2pf(P1-P2-zxgxpf)

Q2/ A simple jet carburetor has to supply 5 Kg of air per minute. The air is at a pressure of 1.013 bar

and a temperature of 27 °C. Calculate the throat diameter of the choke for air flow velocity of 90 m/sec.

Take velocity coefficient to be 0.8. Assume isentropic flow and the flow to be compressible.

Quiz/ Determine the air-fuel ratio supplied at 5000 m altitude by a carburetor which is adjusted to give

an air-fuel ratio of 14:1 at sea level where air temperature is 27 °C and pressure is 1.013 bar. The

temperature of air decreases with altitude as given by the expression

The air pressure decreases with altitude as per relation h = 19200 log10 (1.013), where P is in bar. State

any assumptions made.

t = ts

P

0.0065h

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps with 3 images

Knowledge Booster

Similar questions

- Hom Work عماد داود عبور (35) Q18 The Fiat car has a four strok engine of 1089 C.C capacity.It develops maximum power 32kw at 5000 r.p.m. The volumetric efficiency at this speed is 75% and the air-fuel ratio 13:1, At peak power the theoretical air speed at the choke is 120 m/sec. The coefficient of discharge for the venturi is 0.85 and that of the main petrol jet is 0.66. An allowance should be made for the emulsion tube, the diameter of which can be taken as (1/2.5) of the choke diameter. the Petrol surface is 6 mm blow the choke at this engine condition. Calculate the size of a suitable choke (D) and main jet (d).The specific gravity of Petrol is 0.75 andthe Latmospheric pressure 1.03 bar and temperature 27°c. [D=23.2mm,d=1.296mm]arrow_forwardQ2 An automotive engine has a bore of 90 mm; the stroke is 110 mm; and the length of the connecting rod is 166 mm Knowing that the volume of the combustion chamber is 75 cm³ and the intake valve closes 18° crank angle degree after BDC. If injection Started 10 degrees before TDC and ends 40 degree after TDC. And the engine is running at 3000 rpm. a. Calculate the geometrical compression ratio and the actual compression ratio? b. Find the ratio between the maximum speed of the piston to the mean piston speed for this engine? c. Find the injection periodarrow_forwardFor the double acting cylinder shown, what flow sequence will happen when the lever (operator) is pulled away from the valve body?arrow_forward

- Q40 The venturi of a simple carburettor has a throat diameter of 35 mm and aid the coefficient of air flow is 0.85. The fuel orifice has a diameter of 2.3 mm and the coefficient of fuel flow is 0.66. The petrol surface is 5mm below the throat Find The air Fuel ratio for a pressure drop of 0.07 bar when nozzle lip is neglected. ⑥The air Fuel ratio when the nozzle lip is taken into account win wilt to tout The minimum velocity of air (critical air velocity) required to start The fuelut size flow when nozzle lip is provided. [used Approximate method Just Take density of air and fuel as 1.2 and 750 kg/m³ respectively) Enter APS Answers [a_11.93 b-11-96 c_7.83 m/sec ] 2-1 1920arrow_forwardAn inward flow reaction turbine works under a head of (22.5 m).The external andinternal diameters of therunner are(1.35 and 1m)respectively.The angle of guide vanesis (15°)and the moving vanes are radial at inlet.Radial velocity of flow through the runneris constant and there is no velocity of whirl at outlet.Determine the speed of the runnerin rpm and the angle of vane at outlet.If the turbine develops (375 kW),find the specificspeed.Neglect friction losses.[Ans.206.5 rpm,19°53',81.6]arrow_forward| Centrifugal pump impeller runs at 950 rpm. Its external and internal diameters are 500 mm and 250 mm. The vanes are set back at an angle of 35° to the outer rim. If the radial velocity of water through the impeller be maintained constant as 2 m/sec, find the angle of the vanes at inlet, the velocity and direction of water at outlet and the work done by the impeller per kg of waterarrow_forward

- Answer the problem correctly and provide complete and readable solutions. If you can explain the process (briefly), please do so. Thank you!arrow_forwardWhat would be the effect on the result of the following systematic errors of measurement! a. The jockey weight in error by 0.001kg. b. The distance from the center of the vane to the pivot of the lever in error by 1mm. C. The diameter of the water jet emerging from the nozzle 0.1mm different from the nozzle diameter. It has heen assumed that the velocity in the let is uniform over the entire cross section.arrow_forward- Categorize air-compressor to dynamic and positive-displacing compressors and distinguish each main category in terms of working concept and flow direction- Distinguish the major differences between centrifugal compressors and axial compressors- List the different types of industrial compressors, provide a brief summary and assessment of each type- Discuss compressor faults and potential hazardsarrow_forward

- John’s automobile has a three-liter SI-V6 engine that operates on a four-stroke cycle at 3600 RPM. The compression ratio is 9.5, the length of connecting rods is 16.6 cm, and the engine is square (B=S). at this speed, combustion ends at 20o at T.D.C. This engine is connected to Dynamometer which gives a brake output torque reading of 205 N-m. At his speed, air enters the cylinders at 85 kPa and 60o C, and the mechanical efficiency of the engine is 85%. Calculate: (a) Brake power, HP || (b) Indicated Power, HP || (c) Brake Mean Effective Pressure, Bmep , Psia || (d) Indicated Mean Effective Pressure, Imep, Psia || (e) Friction Mean Effective Pressure, Fmep, Psiaarrow_forwardQ1/ A simple jet carburetor is required to supply 0.1 kg/s of air and 8.333x10-3 kg/s of fuel of density 780 kg/m³. The air is initially at 1.013 bar and 27 C. Assume the flow is an isentropic and compressible. The air flow velocity 80 m/s of the chock. The pressure drop across the fuel metering orifice is 0.75 of that at the chock. Calculate the throat diameter and orifice diameter? Take the velocity coefficient for the venture to be 0.8 and the coefficient of discharge of the main fuel jet to be 0.6.arrow_forwardcentrifugal compressor has pressure ratio of 4:1 with an isentropic efficiency of 80% when running at 15000 rpm and inducting air of 293° K. Curved vanes at inlet given the air a pre whirl of 25° to the axial direction curved vanes at inlet given the air a pre whirl of 25° to the axial direction at all radil and mean dia of eye is 250 mm. The absolute air velocity at inlet is 150 m/sec. Impellér tip dla 600 mm calculate sliparrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY