Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Question

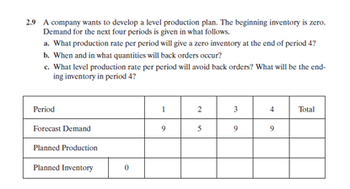

Transcribed Image Text:2.9 A company wants to develop a level production plan. The beginning inventory is zero.

Demand for the next four periods is given in what follows.

a. What production rate per period will give a zero inventory at the end of period 4?

b. When and in what quantities will back orders occur?

c. What level production rate per period will avoid back orders? What will be the end-

ing inventory in period 4?

Period

Forecast Demand

Planned Production

Planned Inventory

0

1

2

3

4

Total

9

5

9

9

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 5 steps with 6 images

Knowledge Booster

Similar questions

- 1. Katherine is a forecast manager. She used exponential smoothing to forecast her sales with alpha equals 0.25. Her forecast for this week was 161 but the actual number is 232. What is her forecast for next week?2. Blue Pad Company’s lead time L is1week and demand rate is119units per week.Holding cost is $29 per unit and ordering cost is $281. Assume 52 weeks in a year.What is the EOQ? Keep two decimal points!3.Blue Pad Company’s lead time L is3week and demand rate is123units per week.Holding cost is $70 per unit and ordering cost is $726. Assume 52 weeks in a year.What is the ROP?4. Lugini Watch’s annual demand is 107. It can produce at a rate of 19 watches per month with a $249 setup cost for the production run. Find the order quantity (EPQ) assuming carrying cost is $57 per unit a year. Keep two decimal points!5. Lugini Watch’s annual demand is 108. It can produce at a rate of 24 watches per month. Using the…arrow_forward7. Nowjuice, Inc., produces Shakewell fruit juice. A planner has developed an aggregate forecast for demand (in cases) for the next six months. Month May Jun Jul Forecast 4,000 4,800 5,600 Aug Sep 7,200 Oct 6,400 5,000 Use the following information to develop aggregate plans. Regular production cost Regular production capacity Overtime production cost Subcontracting cost Holding cost Beginning inventory $10 per case 5,000 cases $16 per case $20 per case $1 per case per month 0 Develop an aggregate plan using each of the following guidelines and compute the total cost for each plan. Which plan has the lowest total cost? a. Use level production. Supplement using overtime as needed. b. Use a combination of overtime (500 cases per period maximum), inventory, and subcontracting (500 cases per period maximum) to handle variations in demand. c. Use overtime up to 750 cases per period and inventory to handle variations in demand.arrow_forward2. Perform an ABC analysis for the data provided. Clearly explain why you classified items as A, B, or C. Annual Unit Item Usage 2400 Cost $19.51 $32.60 $10.20 $6.80 2 6200 3 8500 4 3200 6000 $4.50 $55.70 $3.60 $44.90 $35.62 750 7 8200 8 9000 5800 10 820 $82.60 $40.50 11 500 12 2000 $15.40 $14.60 $35.80 13 2400 14 6300 15 4750 $17.30 2700 $51.75 $42.90 $25.30 16 17 1600 18 1350 19 5000 $67.00 20 1000 $125.00arrow_forward

- .Substitue for Mandatory problem #2 on exam in attachment )-Calculate the Tracking Signal(RSFE/MAD t) given the following data and an alpha=0.4.MAD t-1=15: Period Actual Demand Forecast Demand Error ................... RSFE MAD t TS 0 Start up Start Up Start Up 15 1 30 45 2 43 3 38 4 37 5 40arrow_forwardThe units of Manganese Plus available for sale during the year were as follows: Mar. 1 June 16 Nov. 28 Inventory Purchase Purchase 23 units @ $29 32 units @ $30 42 units @ $36 97 units $667 960 1,512 $3,139 There are 14 units of the product in the physical inventory at November 30. The periodic inventory system is used. a. Determine the inventory cost by the FIFO method. $ b. Determine the inventory cost by the LIFO method. $ c. Determine the inventory cost by the weighted average cost methods. Round intermediate calculations and final answer to two decimal places.arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.