Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN: 9781259696527

Author: J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher: McGraw-Hill Education

expand_more

expand_more

format_list_bulleted

Question

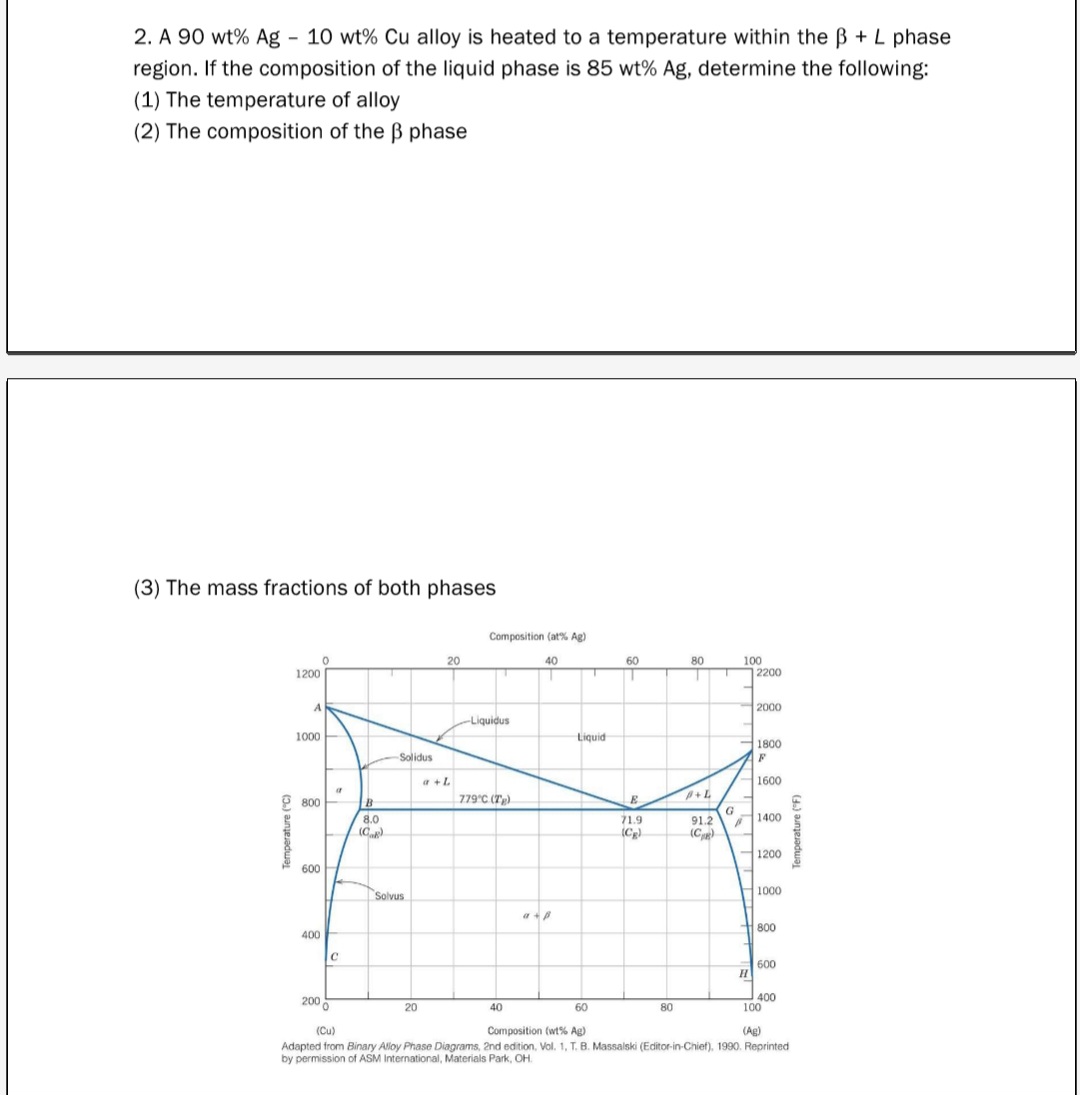

Transcribed Image Text:2. A 90 wt% Ag - 10 wt% Cu alloy is heated to a temperature within the ß + L phase

region. If the composition of the liquid phase is 85 wt% Ag, determine the following:

(1) The temperature of alloy

(2) The composition of the ß phase

(3) The mass fractions of both phases

Temperature (°C)

1200

A

1000

800

600

0

400

a

C

с

2000

B

8.0

(C)

T

Solidus

Solvus

20

20

a + L

Composition (at % Ag)

40

T

Liquidus

779°C (7g)

ap

40

T

Liquid

60

T

E

71.9

(C₂)

80

T

80

P+L

91.2

(C)

G

100

UN

#

H

2200

2000

1800

F

1600

1400

1200

1000

800

60

Composition (wt% Ag)

(Cu)

(Ag)

Adapted from Binary Alloy Phase Diagrams, 2nd edition, Vol. 1, T. B. Massalski (Editor-in-Chief), 1990. Reprinted

by permission of ASM International, Materials Park, OH.

600

400

100

Temperature (°F)

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 5 steps with 6 images

Knowledge Booster

Similar questions

- A one-inch thick steak initially at room temperature is placed inside an oven maintained at 250 o C. Estimate how long it will take for its internal temperature to reach 70 o C. What will be the surface temperature at that time if we assume no steam generation? Include radiation as well as convection (h ~ 3 W/m²/K) in your analysis.arrow_forwardThere's a copper calorimeter container with the mass 0.2 kg and has 0.32 kg of H2O and also 0.036 kg of ice (thermal equilibrium at atm). If we drop 1.5 kg of lead at a temperature of 200 Celsius into calorimeter container, find the final temperature (in Celsius). Lead=131J/kgK Copper=390J/kg.K H2O = Cw = 4190 J/kg.K & LF = 3.34 x 105 J/kgarrow_forward4-2arrow_forward

- 1. Consider a blast furnace which is charged with iron ore, coke and flux with the following composition: Iron ore (weight %): Fe2O3-78, SiO2-8.4, MnO=0.6, Al2O3-5.0, P₂Os=1.7, MgO=1.2 and H2O=5.1 Coke (weight %): C=88, SiO2-9, Al2O3-1 and H₂O=2 Flux (weight %): CaCO3-96%, MgCO3-2% and SiO2=2% And pig iron is produced with the following composition: Pig iron (weight %): Fe =92.7, C=4, Si=2, P=0.9 and Mn=0.4 The coke and flux rates are 900 and 425 kg/ton of pig iron, respectively. During smelting 99.5% of Fe is reduced and 0.5% is slagged. The CO/CO2 ratio in the top gas is 2/1. Calculate a) Weight of iron ore b) Weight and composition of slag c) Volume of air required d) Volume and %composition of exit gas.arrow_forwardResearch for the boiling point of the following mixture of compounds. Encircle which would boil first. Finally, indicate what type of distillation will you use to separate them.arrow_forwardGiven the solidus and liquidus temperatures for a copper-gold. Construct the phase diagram for the system and label each region.arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY

Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Introduction to Chemical Engineering Thermodynami...

Chemical Engineering

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind...

Chemical Engineering

ISBN:9781118431221

Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:WILEY

Elements of Chemical Reaction Engineering (5th Ed...

Chemical Engineering

ISBN:9780133887518

Author:H. Scott Fogler

Publisher:Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:9781285061238

Author:Lokensgard, Erik

Publisher:Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:9780072848236

Author:Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:McGraw-Hill Companies, The