Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

Transcribed Image Text:# Steel Plate Casting Design Overview

## Casting Details

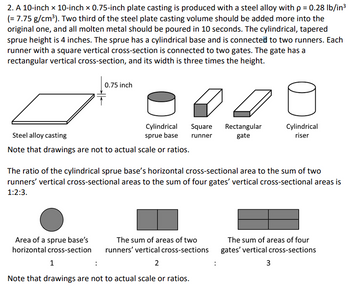

A 10-inch by 10-inch by 0.75-inch steel alloy plate casting is being designed. The steel used has a density of \( \rho = 0.28 \, \text{lb/in}^3 \) (\( = 7.75 \, \text{g/cm}^3 \)). To the original steel plate casting volume, an additional two-thirds of the volume is to be added. The entire molten metal should be poured within 10 seconds.

### Sprue, Runner, and Gate Configuration

- **Sprue**: The sprue is cylindrical and tapered with a height of 4 inches.

- **Base**: The sprue has a cylindrical base.

- **Runners**: Two runners are connected to the sprue base. Each runner has a square vertical cross-section.

- **Gates**: Each runner connects to two gates, which have a rectangular vertical cross-section. The width of each gate is three times its height.

> **Note**: Drawings are illustrative and not to scale or ratio.

### Cross-Sectional Area Ratios

The areas of the various components relate as follows:

- The ratio of the cylindrical sprue base's horizontal cross-section area to the sum of the vertical cross-sectional areas of the two runners, and then to the sum of the vertical cross-sectional areas of four gates, is 1 : 2 : 3.

### Diagram Explanation

The diagram illustrates:

1. **Cylindrical Sprue Base**: Shown as a circle representing its horizontal cross-section.

2. **Runners**: Illustrated by two adjoining squares signifying their vertical cross-sectional areas.

3. **Gates**: Represented by four adjoining rectangles.

> **Note**: Diagrams focus on explaining the concept and are not drawn to actual scale or proportions.

![The height of the cylindrical riser is 1.75 times its diameter, so it takes 30% longer for the riser to solidify compared to the solidification time of the steel plate casting. The dynamic viscosity of steel is \(4 \times 10^{-3} \, \text{lb/ft/S} (= 6 \, \text{cP} = 6 \times 10^{-3} \, \text{Pa} \cdot \text{S})\), and the mold constant = \(16 \, \text{min/in}^2\). The gravitational acceleration is \(32.2 \, \text{ft/s}^2\).

Determine the following, showing your work clearly:

(a) Based on the problem statement, sketch an isometric view of a pattern with all components, such as sprue, sprue base, runners, gates, riser, and so on, required for this casting process. Include a label for each component. Note that the sketch is not necessary to have actual scale or ratios.

(b) The cylindrical sprue base’s horizontal cross-section diameter. Note that your answer should be in [in].

(c) The dimensions of each runner’s vertical cross-section. Note that your answer should be in [in].

(d) The dimensions of each gate’s vertical cross-section. Note that your answer should be in [in].

(e) The dimensions of the cylindrical riser. Note that your answer should be in [in].](https://content.bartleby.com/qna-images/question/073654f7-f6ae-4088-9c12-c0cdcc78aade/6d527c35-3d33-4f22-a809-cb74394f025f/14hveed_thumbnail.png)

Transcribed Image Text:The height of the cylindrical riser is 1.75 times its diameter, so it takes 30% longer for the riser to solidify compared to the solidification time of the steel plate casting. The dynamic viscosity of steel is \(4 \times 10^{-3} \, \text{lb/ft/S} (= 6 \, \text{cP} = 6 \times 10^{-3} \, \text{Pa} \cdot \text{S})\), and the mold constant = \(16 \, \text{min/in}^2\). The gravitational acceleration is \(32.2 \, \text{ft/s}^2\).

Determine the following, showing your work clearly:

(a) Based on the problem statement, sketch an isometric view of a pattern with all components, such as sprue, sprue base, runners, gates, riser, and so on, required for this casting process. Include a label for each component. Note that the sketch is not necessary to have actual scale or ratios.

(b) The cylindrical sprue base’s horizontal cross-section diameter. Note that your answer should be in [in].

(c) The dimensions of each runner’s vertical cross-section. Note that your answer should be in [in].

(d) The dimensions of each gate’s vertical cross-section. Note that your answer should be in [in].

(e) The dimensions of the cylindrical riser. Note that your answer should be in [in].

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 6 steps with 11 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY