Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN: 9781259696527

Author: J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher: McGraw-Hill Education

expand_more

expand_more

format_list_bulleted

Question

Transcribed Image Text:2) Flash Distillation (or Single-Stage Contact)

A mixture of 60 mole % n-heptane and 40 mole % toluene is vaporized at 101.325 kPa (absolute) until 40

moles of vapor and 60 moles of liquid in equilibrium with each other are produced. This occurs in a single-

stage system and the vapor and liquid are kept in contact until equilibrium is achieved. Calculate the

composition of the vapor and liquid.

Note: Assume the system exhibits ideal behavior (which it mostly does), e.g. Raoult's Law applies and an

Antoine's Vapor Pressure correlation is a sufficiently accurate model of component vapor pressure.

Transcribed Image Text:0

1

2

3

4

5

LO

6

7

8

9

20

21

22

23

24

25

26

27

Ready

A

B

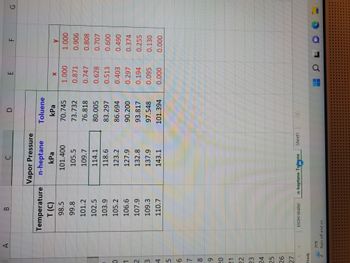

Temperature

T (C)

98.5

99.8

101.2

102.5

103.9

105.2

106.6

107.9

109.3

110.7

EtOH-Water

71 F

Rain off and on

C

Vapor Pressure

n-heptane

kPa

101.400

105.5

109.7

114.1

118.6

123.2

127.9

132.8

137.9

143.1

n-heptane-Toluene Sheet1

D

Toluene

kPa

70.745

73.732

76.818

80.005

83.297

86.694

90.200

93.817

97.548

101.394

E

X

1.000

0.871

0.747

0.628

0.513

0.403

0.297

0.194

0.095

0.000

F

Y

1.000

0.906

0.808

0.707

0.600

0.490

0.374

0.255

0.130

0.000

HO COLO

G

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 6 steps with 4 images

Knowledge Booster

Similar questions

- A single effect evaporator is used to concentrate 10 000 kg / hr of tomato juice from 5% total solids to 30% total solids. The juice enters the Evaporator at 20 ° C. The evaporator is operated on Steam (80% quality) at 143.27 kPa. The vacuum in the evaporator allows the juice to boil at 75 ° C. The specific heat of the dilute material is 4.1 kJ / (kg ° C) and the concentrate product is 3.1 kJ / (kg ° C). Count it a. Steam demand rate = ..... kg / hour. b. Steam economy when condensate temperature is released at 75 ° C. = .... (kg of water evaporated / kg of steam)arrow_forwardShow calculation alsoarrow_forwardFruit juices at 25 °C containing 5% total solids were concentrated via a single effect evaporator. The evaporator is operated in a vacuum at an evaporation temperature of 80 °C, and 85% quality steam is supplied at 169.06 kPa. The desired concentration of the final product is 40% total solids. The rate of concentrated product leaving the evaporator is 3000 kg / hour. The specific heat of fruit juice is 4.05 kJ / (kg °C), and the concentrated product 3.175 kJ / (kg °C). Count : a. The required steam rate is = Answer kg / hour. b. Steam economy if the condensate temperature cannot be released at 90 °C. = Answer (kg evaporated air / kg vapor)arrow_forward

- A feed column has the composition given in the table below, and it at as a pressure of 30 bar and at a temperature of 400C. Calculate the flow of the liquid and vapor phases. Feed kmol/h ethane 20 propane 20 isobutane 20 n-pentane 20arrow_forwardThe lower heating value for gaseous n-octane is 44,791 kJ/kg, and its latent heat of vaporization is 300 kJ/kg. Using this information, determine the enthalpy of formation at 298 K for liquid n-octane in kJ/kmol. (Here you are to compute the enthalpy of formation from the given information, not look it up in a property table.)arrow_forwardA one-inch thick steak initially at room temperature is placed inside an oven maintained at 250 o C. Estimate how long it will take for its internal temperature to reach 70 o C. What will be the surface temperature at that time if we assume no steam generation? Include radiation as well as convection (h ~ 3 W/m²/K) in your analysis.arrow_forward

- A single effect evaporator was used to concentrate 8000 kg / hr of tomato juice from 5% total solids to 30% total solids. The juice enters the evaporator at 15 ° Celsius. The evaporator was operated by steam (80% quality) at 143.27 kPa. The vacuum in the evaporator allows the juice to boil at 80 ° Celsius. the specific heat of the Ecer material is 4.1 KJ / (kg degrees Celsius) and the concentrate product is 3.1 KJ / (kg degrees Celsius). Count it a. Steam demand rate = b. Steam economy if Condensate temperature is released at 75 ° Celsius =arrow_forwardAs part of a constant pressure calorimetry experiment for a reaction in water, you measured a temperature change from 275 K to 300 K for the water in the calorimeter. How much heat in Joules was released by the reaction if the calorimeter had 10 mL of water in it (assuming that the density of water = 1.0 g/mL)?arrow_forwardPlease include your diagram, mass balances, and full work. Thank you.arrow_forward

- 05: Acetylene gas (C₂H₂) at 25 °C is burned during a steady-flow combustion process with 30 percent excess air at 27 °C. It is observed that 75x10³ kJ of heat is being lost from the combustion chamber to the surroundings per kmol of acetylene. Assuming combustion is complete, determine the exit temperature of the product gases.arrow_forward3arrow_forwardA single effect evaporator was used to concentrate 8000 kg / hr of tomato juice from 5% total solids to 30% total solids. The juice enters the Evaporator at 20 ° C. The evaporator is operated on Steam (85% quality) at 143.27 kPa. The vacuum in the evaporator allows the juice to boil at 80 ° C. The specific heat of the dilute material is 4.1 kJ / (kg ° C) and the concentrate product is 3.1 kJ / (kg ° C). Count it (a) Steam demand rate = Answerkg / hour. b. Steam economy when condensate temperature is released at 75 ° C. = Answer(kg of water evaporated / kg of steam)arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY

Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Introduction to Chemical Engineering Thermodynami...

Chemical Engineering

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind...

Chemical Engineering

ISBN:9781118431221

Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:WILEY

Elements of Chemical Reaction Engineering (5th Ed...

Chemical Engineering

ISBN:9780133887518

Author:H. Scott Fogler

Publisher:Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:9781285061238

Author:Lokensgard, Erik

Publisher:Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:9780072848236

Author:Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:McGraw-Hill Companies, The