Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

Question 13! This is applied

Transcribed Image Text:13. One kg of pure liquid water at 0°C is placed into an insulated tank containing 5 kg

of seawater of salinity 3 percent and initial temperature 17.5°C. The system is al-

lowed to reach equilibrium. Calculate the final temperature of the system. Express

your answer in °C.

Expert Solution

arrow_forward

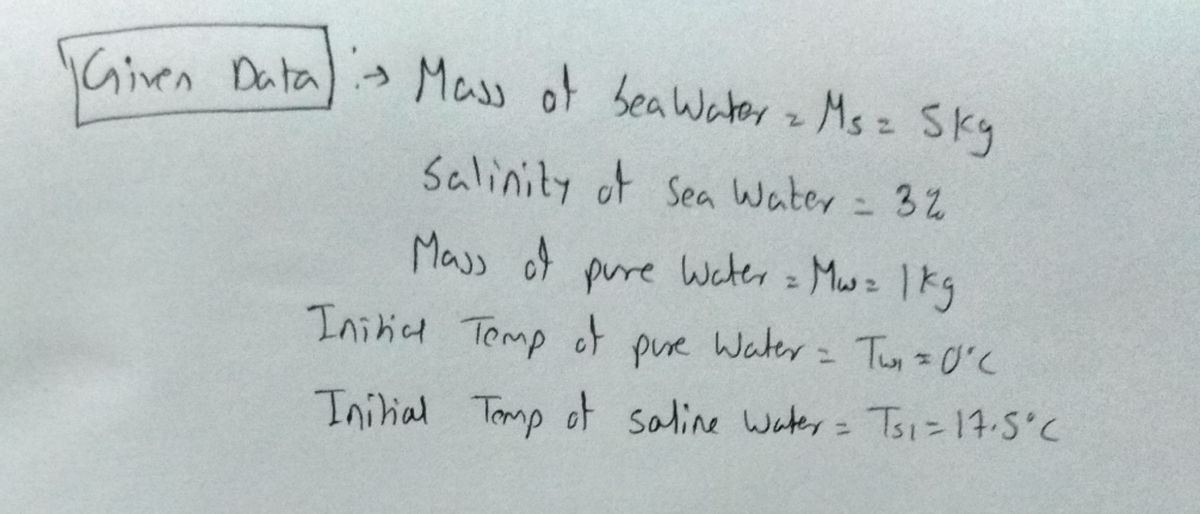

Step 1 Given Data

Trending nowThis is a popular solution!

Step by stepSolved in 3 steps with 3 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- An iron grade has a melting point of 2200°F. Its specific heat = 0.11 Btu/lbm°F, and its heat of fusion = 56.2 Btu/lbm. A 150-lbm block of this cast iron is to be melted. Determine how much heat is required to raise its temperature from 70°F to its melting point and transform it from the solid to liquid phase. Do not use a comma in your answer. Recall: Required heat H = mC(Tm – Ta) + mHfarrow_forwardHello Sir.Good Night I have a question in my homework related chemical material lesson. The following below is my question.Please advice, thank you. "Explain the stages of the metal strengthening process ?"arrow_forwardAnswer the following questions based on the given information in the table and further calculation (if needed for any missing parameter, e.g. strain at yield point). Assume all metals started with the same shape and size before the tensile tests occurred. Material A B C D E Yield Strength (MPa) 105 600 430 355 The material that experienced the greatest percent reduction in area is material The hardest material is material The hardest material has Tensile Strength (MPa) The material that experienced the greatest percent reduction in area has 135 850 The material that experienced the largest change in shape before plastic deformation occurred is material The stiffest material is material The stiffest material has 535 365 Fracture before yielding The material that experienced the largest change in shape before plastic deformation occurred has Strain at Fracture [Choose ] [Choose ] [Choose ] [Choose ] [Choose ] [Choose ] [Choose ] [Choose ] 0.45 0.15 0.20 0.25 Fracture Strength (MPa)…arrow_forward

- [Thermodynamics] kindly Answer it Correctly with explanation, If you are not sure skip it. 1) Evaluate whether the following statement is True or False: For an ideal gas, the change in enthalpy is equal to Cp (specific heat at constant pressure) times the change in temperature. “This relationship can be used for both constant volume and constant pressure processes.” -True -False -It depends, only true or false under certain circumstancesarrow_forwardNeed help on this Qarrow_forwardGive two reasons why it is important to pay attention thermal expansion and contraction in real life situations.arrow_forward

- I need help on parts a and b, please. Part a is incorrect and I have no clue how to solve it correctly, please help. Thank you!arrow_forward(Thermodynamics) Plz solve the question and show the stepsarrow_forwardThe properties of some very ductile metals, such as certain low- carbon steels, change at low temperatures at their particular transition zone. How can this information help an engineer design machinery that will be operating in subzero temperatures?arrow_forward

- This question is for mechanical engineering. Please help me with this and explain. Thank you.arrow_forwardb) A 1.25 m long cable has a diameter 3.50 mm with a Young's Modulus, E, of 9.75 x 10⁹ N/m². When the wire is placed under tension, it experiences a stress of 202.52 x 106 N/m², the length of the cable extends by 36.35 mm. Calculate the force that the cable experiences under tension and the strain energy density (U/V) due to deformation. Give your answers in newtons (N) to 2 decimal places for the force; and in joules per cubic metre (J/m³) for the strain energy density to 2 decimal places. Assume the cable is solid and the material is homogeneous. c) Figure Q1c shows a bracket on rollers that allow the bracket to move along a beam in the horizontal direction. A force F₁ of 2625 N acts at point A where the angle between F, and the x-axis is 100. If force F₂ acts at an angle a = 400 between F2 and the y-axis: (i) Determine the magnitude of F2 necessary to maintain bracket on horizontal equilibrium. (ii) Determine the vertical force at A acting along the y-axis. Give your answers to the…arrow_forwardQuestion 1 You are working on a design team at a small orthopaedic firm. You have been asked to select a cobalt- chrome-molybdenum (CoCr) material that will not experience plastic deformation under a specific mechanical test, as follows... A tensile stress is applied along the long axis of a solid cylindrical rod that has a diameter of 10 mm. An applied load of some magnitude F produces a 7x10³ mm change in diameter (see figure below, original shape is blue, elongated shape is unshaded). Q1H: Provide a brief rationale based on calculations used to support your answer. That is, how would you explain the behavior of the "new alloy" material to your design team? Table of properties: Assume Poisson's ratio is 0.3 for all materials Process Elastic Modulus (GPa) Material CoCr F75 As cast/Annealed 210 CoCr F90 Hot forged New alloy Z X ↑ F df O 210 110 Yield Strength (MPa) 450-517 900-1200 600 Tensile Strength (MPa) 655-890 1400-1600 700arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY