Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

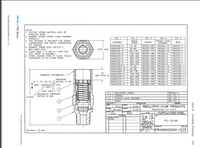

1.How many assemblies are described by this one assembly drawing?

2. Each assembly described by this drawing uses this one part. What is its part number?

3.Which BODY is used for ASSEMBLY PRV9433T-E?

4. How many BODY options are there on this drawing?

5. How will the date code be applied to the assembly?

6. What paper size is the original version of the print?

7. Who checked the drawing? Exactly how it is on the print.

8. What is the scale of the original drawing?

9.Are there any reference measurements on the drawing?

10. Are there any cutting planes on this drawing?

Thank you, please help.

Transcribed Image Text:NOTES:

1. CAUTION: SPRING MATERIAL MUST BE

STAINLESS STEEL.

2. DRAWING SHOWS SPRING GUIDE ASSEMBLY

PRV250-4.

3. THIS DISTANCE IS REQUIRED FOR SPRING

COMPRESSION, AND SEAT'S COMPRESSION

COL 1

COL 2

COL 3

COL 4

COL 5

RANGE

(PSIG)

SPRING GUIDE

ASSEMBLY

ASSEMBLY

SPRING

BODY

SET REMOVAL.

4. DRAWING SHOWS BODY PRV375-1,

WITH WEEP HOLE.

5. CLEAN ITEMS 1-4 PER B-11550-400

JUST PRIOR TO ASSEMBLY.

6. STORE CLEANED ITEMS IN CLEAN, SEALED

PRV9433F-A

10-39

BX250-025

PRV250-10

PRV375-1

40-89

BX250-065

BX250-115

PRV250-10

PRV250-10

PRV375-1

(.875 HEX) PRV9433F-B

PRV9433F-C

PRV9433T-D

PRV9433T-E

PRV9433T-F

PRV9433T-G

PRV9433T-H

PRV9433FP-A

PRV9433FP-B

PRV9433FP-C

PRV9433TP-D

PRV9433TP-E

PRV9433TP-F

PRV9433TP-G

PRV9433TP-H

90-139

140-199

200-299

300-379

PRV375-1

BX250-180

BX250-260

BX250-340

PRV250-4

PRV375-1

PRV375-

PRV375-1

PRV375-1

PRV375-1

PRV250-4

PRV250-4

CONTAINERS IN THE CLEAN ROOM.

380-459

460-550

10-39

BX250-420

PRV250-4

PRV250-4

BX250-500

BX250-025

BX250-065

BX250-115

BX250-180

BX250-260

BX250-340

BX250-420

BX250-500 PRV250-4

PRV250-10

PRV375P-1

PRV375P-1

40-89

90-139

PRV250-10

PRV250-10

PRV375P-1

PRV375P-1

PRV375P-1

PRV375P-1

PRV375P-1

PRV375P-1

.50

140-199

PRV250-4

STAMPING INFORMATION

(SEE NOTE 3)

200-299

PRV250-4

PRV250-4

PRV250-4

PRESSURE

300-379

(F, T, FP, OR TP) SETTING IN PSI

REGO PRV9433CJPSI

25 BAR CJ

(4

380-459

460-550

DATE CODE

EQUIVALENT PRESSURE

SETTING IN BAR

4 1 ADJUSTING SCREW

3 1 SPRING

2 1 SPRING GUIDE ASSEMBLY

1 1 BODY

ITEM QTY.

PRV250-3

SEE COL 3

SEE COL 4

(2.625)

SEE COL 5

NUMBER

DESCRIPTION

DRANN

ENGINEER

T. TICKLE

J. OLSEN

CHECKED

GR

D. WILLIAMS

REGO, CRYO-FLOW PRODUCTS

BURLINGTON, N.C. 27215

APPROVED

J. OLSEN

ORIGINAL DATE

05/25

PLOT GENERATEDT

08/02

THIS DRAWING IS ECI PROPRIETARY INFORMATION

ALL RIGHTS OF DESIGN OR INVENION ARE RESERVED

UNLESS

OTHERWISE SPECIFIED:

* 015

* 02

*005

+ 0005

REVISIONS

TTLE

A206, 05/25

AlsSUED

2 PL DEC.

3 PL DEC.

i PL DEC.

ANGLES

PRV BLANK

CONCENTRICITY 010 FIM

FINISH 125 MAX

REMOVE BURRS, BREAK

SHARP EDGES R015 MAX

INTERPRET DIMENSIONS & DRAWING NO.

TOLERANCES AW

ASME YI4.SM-1994

DWG SIZE

SOLE (2:1)

PRVO09433XX-XB

A-CHANGES

0-GAGES

Unit 16 Assembly Drawings 335

Print supplied by Rego Cryo-Flow Produe

PR 16-1. PRV Blank.

Copyright Goodheart-Willcox Co., Inc

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- Required information Sally is making a sine bar, which is used to machine angles on parts (see the given figure). She has a 1.250-inch-thick bar that needs 90° grooves machined into it for precision ground 1.0000-inch diameter cylinders. A sine bar is used by placing different thicknesses under one of the cylinders so that the proper angle is attained. Sally wants the distance between the centers of the cylinders to be D= 5.4 inches. -D -1.0000 Ø How deep should she mill the 90° grooves so that the top of the sine block is 2 inches tall? The depth of the mill should be inches.arrow_forwardI need answers to questions 1, 2, and 3 pertaining to the print provided. Note: A tutor keeps putting 1 question into 3 parts and wasted so many of my questions. Never had a issue before until now, please allow a different tutor to answer because I was told I am allowed 3 of these questions.arrow_forwardA company is reviewing its policy of putting each sub-assemblybought in from outside through a detailed inspection process ondelivery. The firm can either inspect or not inspect. The sub-assemblymay either come up to the required quality standard (90 % of thetime), or fail to do so (10 % of the time).It costs K10 to inspect a sub-assembly and another K10 to put rightany defect found at that stage. If the sub-assembly is not inspected Page 4 of and is then found to be faulty at the finished goods stage the cost ofrework is K40.Advise the firm what to do.arrow_forward

- An engineer draws an assembled gear in perspective. © 2019 StrongMind How does this gear appear when viewed from above? Ⓒ2020 StrongMind Ⓒ2020 StrongMindarrow_forwardwhat are some Observation and Description of Experimental Setup of key failure using bending testarrow_forwardNeed questions 13, 14, 15 explained and answered please.arrow_forward

- Alert for not submit AI generated answer. I need unique and correct answer. Don't try to copy from anywhere. Do not give answer in image formet and hand writingarrow_forwardO b. 2:1 Oc. 1:2 O d. T: 1 QUESTION 10 What is the maximum tensile load P that can be applied to the bolted joint if the bolt diameter is 20 mm and the shear strength of the bolt material is 120 MNm 2 ? Apply a 'safety factor' of 1.2 in your calculations. Note: Please read about 'safety factors' and how they are applied in calculations. O a. 26.4 Nm2 O b. 26.4 kN O c. 62.5 kN O d. 62.5 MNm2 QUESTION 11arrow_forwardWhat are the TPI and TPF of a part with end diameters of 3/4" and 1/2" and a taper length of 4.25"?arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY