Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

thumb_up100%

Please show and explain how to get each value

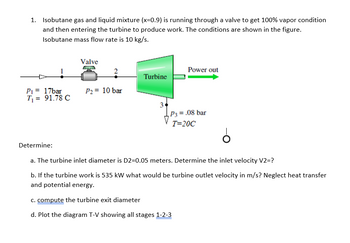

Transcribed Image Text:1. Isobutane gas and liquid mixture (x=0.9) is running through a valve to get 100% vapor condition

and then entering the turbine to produce work. The conditions are shown in the figure.

Isobutane mass flow rate is 10 kg/s.

Valve

20

Power out

Turbine

P₁ =

17bar

T₁ = 91.78 C

P2 = 10 bar

3

P3= .08 bar

T=20C

Determine:

a. The turbine inlet diameter is D2=0.05 meters. Determine the inlet velocity V2=?

b. If the turbine work is 535 kW what would be turbine outlet velocity in m/s? Neglect heat transfer

and potential energy.

c. compute the turbine exit diameter

d. Plot the diagram T-V showing all stages 1-2-3

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps with 1 images

Knowledge Booster

Similar questions

- The inlet of a nozzle is at 400K and the outlet is 300K. The nozzle operates with air as an ideal gas as the working fluid and the flow is isentropic. The flow velocity in the inlet is 2 m/s, vith pressure of 10 bar and di ameter of 15 cm. The gas constant for air is R = 0.287 kJ/kg*K. Solve for the outlet velocity and diameter.arrow_forwardA four-stage compressor works between limits of 1 bar and 120 bar. The indexof compression in each stage is 1.25, the temperature at the start ofcompression in each stage is 30 ˚C, and the intermediate pressure areselected such that work is divided equally among the stages. If the clearanceis negligible: Calculate: 1. the volume of free air delivered per kilowatt-hour at 1.013 bar and 20 ˚C2. isothermal work input 3. isothermal efficiency.arrow_forwardAir at a 800 kPa and 1300 K enters a turbine which has an isentropic efficiency of 90% with a mass flow rate 6 kg/s. The outlet pressure is 100 kPa and assume that specific heats vary with temperature. 1. What is the outlet temperature in K? Report your answer to one decimal place using rounding. 2. (image)arrow_forward

- Read the problem carefully and provide complete solutions with derivation of formulas (integrals and derivatives). Complete solution and units please. Use two decimal plaas for final answers only. 3 min 5. A time- stage compressor receives air at 100 ft³ at 10 psia and the discharge pressure is pressure is 200 psia. If the temperature of the air received is 50 F, find the intercooler pressure, total compresser work and total heat rejected at the intercoolers Answer: 44.72 psia, 16. 31 hp, Bty 345.80 minarrow_forwardI need help with some review problemsfor thermo! thank you Air at 100 kPa and 280K is compressed steadily to 600 kPa and 400K in an air compressor. The mass flow rate of air through the compressor is 0.02 kg/s and the compressor a heat loss of 16 kJ/kg from the compressor occurs. Assuming steady state steady flow conditions and ideal gas behavior (with constant specific heats, Cp=1.009 kJ/kgK, R=0.287 kJ/kgK, determine: a)The necessary power input to the compressor (kW).b)The volumetric flow rate of air at the exit of the compressor (m3/s).arrow_forwardThe steam rate to a turbine for variable output is controlled by a throttle valve in the inlet line.Steam is supplied to the throttle valve at 1,700 kPa and 225°C. During a test run, the pressure atthe turbine inlet is 1000 kPa, the exhaust steam at 10 kPa has a quality of 0.95, the steam flowrate is 0.5 kg/s, and the power output of the turbine is 180kW. 1. What are the heat losses from the turbine? 2. What would be the power output if the steam supplied to the throttle valve were expandedisentropically to the final pressure?arrow_forward

- Finding exit temperature in F, and volumetric flow rate. Step by step solution please thank youuuarrow_forwardSolve the following problem and show your complete solutions for better understanding.arrow_forwardAir with a pressure of 0.1 MPa and a temperature of 25oC with a flow rate of 5.29 kg/minute enters a three-stage reciprocating piston compressor with intercooler. The air is compressed polytropically (n = 1.3) to reach the pressure of 4 MPa. Calculate: a) The pressure at stage-2 and stage-3 so that the compression work is minimum? b) The compression work in each stage and the total compression work? c) The outlet air temperature from each stage's cylinder? d) The amount of heat transferred to each intercooler? e) How much air is needed for cooling in the intercooler if the allowable maximum temperature changes between the inlet and outlet of the intercooler is 8oC?arrow_forward

- could you help me with this problemarrow_forwardAnswer the problem correctly and provide complete and readable solutions. If you can explain the process (briefly), please do so. Thank you!arrow_forwardFor air properties use online source: https://www.peacesoftware.de/einigewerte/luft_e.html The compressor is operating at steady-state increasing pressure of R-22 refrigerant from 4 bars to 14 bars. Temperature was rising during the process from 12C to 90C. The inlet volumetric flow rate is 1 m3/min and inlet diameter is 0.03m. At the exit the diameter is the same. Heat flow to the surroundings can be neglected. Determine: a.Mass flow rate [kg/s] b. Inlet and outlet velocity [m/s] c.Power required to run the compressor [kW]arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY