Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

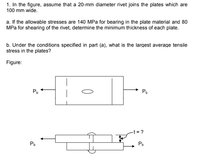

Transcribed Image Text:1. In the figure, assume that a 20-mm diameter rivet joins the plates which are

100 mm wide.

a. If the allowable stresses are 140 MPa for bearing in the plate material and 80

MPa for shearing of the rivet, determine the minimum thickness of each plate.

b. Under the conditions specified in part (a), what is the largest average tensile

stress in the plates?

Figure:

P.

PD

-t = ?

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- t=10 mm b=240 mm F.S=1.9 σall=230 MPaarrow_forwardPipe (2) is supported by a pin at bracket C and by tie rod (1). The structure supports a load P at pin B. Tie rod (1) has a diameter of 15 mm and an allowable normal stress of 175 MPa. Pipe (2) has an outside diameter of 52 mm, a wall thickness of 8 mm, and an allowable normal stress of 175 MPa. Assume x1 = 2.9 m, x2 = 1.4 m, and y1 = 3.8 m. Determine the maximum load Pmax that can be supported by the structure without exceeding either allowable normal stress. B (1) C Answer: Pmax i kNarrow_forwardP (1) B A A metal rod having two different diameters is loaded by an axial force P. Segments (1) and (2) are circular section diameters of 50 mm and 25 mm, respectively. If the normal stress in (1) is 40 MPa. Determine the following: The area of Segment (1) is equal to in mm?: The area of Segment (2) is equal to in mm²: The axial force (P) is equal to in kPa: The Normal Stress in Segment (2) is equal to in MPa:arrow_forward

- 4. The stepped circular bar shown below is made from aluminum (E = 70 GPa, v = 0.35). Each segment is 400 mm in length. Prior to applying the loads, the bar has the dimensions shown. The structure is axially loaded as shown. Determine the stress in each segment, the maximum stress and its location, the final in length of the structure, and the final diameters of each segment due to the applied loads. All dimensions shown are in mm. Ø 25 40 15 ↑ Fu 300 kN 600 kN 300 kNarrow_forwardQuestion 1 Two circular rods of 50 mm diameter are connected by a knuckle joint, as shown in Figure 1, by a pin of 40 mm in diameter. If a pull of 120 kN acts at each end, find the tensile stress in the rod and shear stress in the pin. 50 x 11.00 in Rod (1) Pin Rod (2)arrow_forwardAxial loads are applied with rigid bearing plates to the solid cylindrical rods shown. The normal stress in aluminum rod (1) must be limited to 20 ksi, the normal stress in brass rod (2) must be limited to 24 ksi, and the normal stress in steel rod (3) must be limited to 12 ksi. Determine the minimum diameter required for each of the three rods. Assume P = 8 kips, Q = 5 kips, R = 20 kips and S = 28 kips. Calculate F1, F2, F3 and..arrow_forward

- Part 1. A composite assembly of length, L-375 mm, consisting of a steel (G-77 GPa) core (2) connected by rigid plates at the ends of an aluminum [G-35 GPa) tube (1) is shown. The aluminum tube has outside diameter D₁ - 50 mm and inside diameter d₁-30 mm. = 100 MPa, and the The solid steel core has diameter d₂-25 mm. The allowable shear stress of aluminum tube (1) is (rallow) allowable shear stress of steel core (2) is (Tallow)2= 135 MPa. Determine (a) the allowable torque T that can be applied to the composite shaft. (b) the corresponding torques produced in tube (1) and core (2). (c) the angle of twist produced by the allowable torque T. T D₁ L Calculate the polar moment of inertia, J₁, of the aluminum tube. Answer: J₁ (106) mm².arrow_forwardDetermine the maximum axial force that can be applied to the bar shown in Figure 3. The allowable stress is 100 MPa. The dimensions are: Hole diameter 20 mm. Thickness of bar: 6 mm D = 40 mm d%3D20mm Fillet radius, r = 4 mm 40mm 20 mm r 4 mm 20 mm Figure 3 P.arrow_forwardThe bolted connection illustrated below comprises one bolt and two plates. The bolt, which has a diameter of 20 mm, is threaded through a 22- mm diameter hole in both plates. The shear stress of the bolt is 78,000 MPa. Based on this information, determine the following What is the largest force F that can be placed on the joint without shearing the bolt? what is the normal stress, at the gross section area, in each plate? what is the normal stress, at the net section area, in each plate? what is the bearing (or contact) stress between the bolt and each plate?arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY