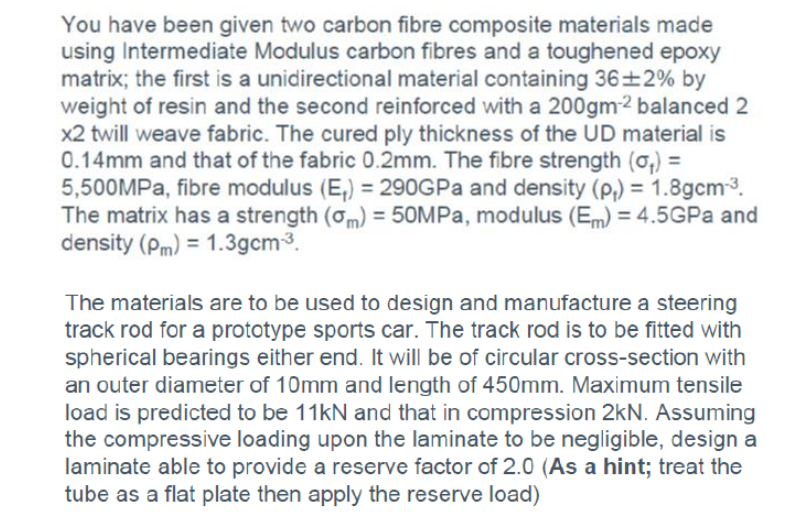

You have been given two carbon fibre composite materials made using Intermediate Modulus carbon fibres and a toughened epoxy matrix; the first is a unidirectional material containing 36±2% by weight of resin and the second reinforced with a 200gm-2 balanced 2 x2 twill weave fabric. The cured ply thickness of the UD material is 0.14mm and that of the fabric 0.2mm. The fibre strength (o,) = 5,500MPa, fibre modulus (E₁) = 290GPa and density (p₁) = 1.8gcm-³. The matrix has a strength (m) = 50MPa, modulus (Em) = 4.5GPa and density (Pm) = 1.3gcm-3. The materials are to be used to design and manufacture a steering track rod for a prototype sports car. The track rod is to be fitted with spherical bearings either end. It will be of circular cross-section with an outer diameter of 10mm and length of 450mm. Maximum tensile load is predicted to be 11kN and that in compression 2kN. Assuming the compressive loading upon the laminate to be negligible, design a laminate able to provide a reserve factor of 2.0 (As a hint; treat the tube as a flat plate then apply the reserve load)

You have been given two carbon fibre composite materials made using Intermediate Modulus carbon fibres and a toughened epoxy matrix; the first is a unidirectional material containing 36±2% by weight of resin and the second reinforced with a 200gm-2 balanced 2 x2 twill weave fabric. The cured ply thickness of the UD material is 0.14mm and that of the fabric 0.2mm. The fibre strength (o,) = 5,500MPa, fibre modulus (E₁) = 290GPa and density (p₁) = 1.8gcm-³. The matrix has a strength (m) = 50MPa, modulus (Em) = 4.5GPa and density (Pm) = 1.3gcm-3. The materials are to be used to design and manufacture a steering track rod for a prototype sports car. The track rod is to be fitted with spherical bearings either end. It will be of circular cross-section with an outer diameter of 10mm and length of 450mm. Maximum tensile load is predicted to be 11kN and that in compression 2kN. Assuming the compressive loading upon the laminate to be negligible, design a laminate able to provide a reserve factor of 2.0 (As a hint; treat the tube as a flat plate then apply the reserve load)

Elements Of Electromagnetics

7th Edition

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Sadiku, Matthew N. O.

ChapterMA: Math Assessment

Section: Chapter Questions

Problem 1.1MA

Related questions

Question

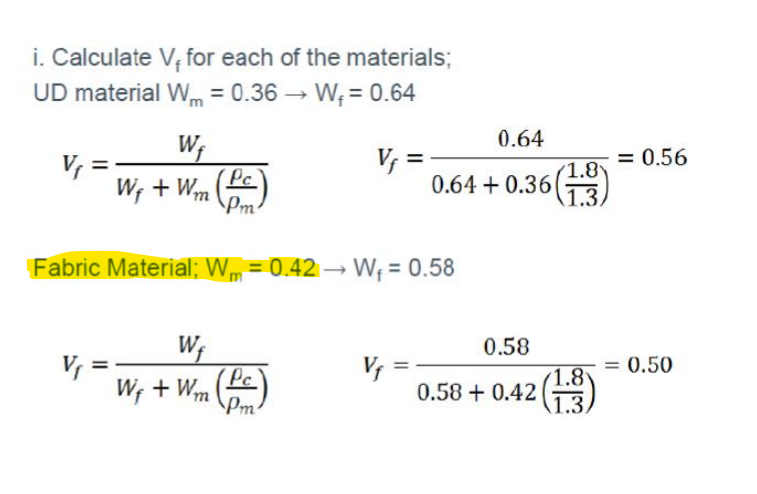

why W of m = 0.42 ??????? I do not understnd this

Transcribed Image Text:You have been given two carbon fibre composite materials made

using Intermediate Modulus carbon fibres and a toughened epoxy

matrix; the first is a unidirectional material containing 36±2% by

weight of resin and the second reinforced with a 200gm-2 balanced 2

x2 twill weave fabric. The cured ply thickness of the UD material is

0.14mm and that of the fabric 0.2mm. The fibre strength (o,) =

5,500MPa, fibre modulus (E₁) = 290GPa and density (p₁) = 1.8gcm-³.

The matrix has a strength (om) = 50MPa, modulus (Em) = 4.5GPa and

density (Pm) = 1.3gcm-³.

The materials are to be used to design and manufacture a steering

track rod for a prototype sports car. The track rod is to be fitted with

spherical bearings either end. It will be of circular cross-section with

an outer diameter of 10mm and length of 450mm. Maximum tensile

load is predicted to be 11kN and that in compression 2kN. Assuming

the compressive loading upon the laminate to be negligible, design a

laminate able to provide a reserve factor of 2.0 (As a hint; treat the

tube as a flat plate then apply the reserve load)

Transcribed Image Text:i. Calculate V₁ for each of the materials;

UD material W=0.36 → W₁= 0.64

V₁ =

Wf

W₁ + Wm

V₁

Pc

Pm²

V₁ =

Fabric Material; W = 0.42 → W₁ = 0.58

Wf

W₁

+ Wm (Pc)

Pm

0.64

1.8

0.64 +0.36 (13)

Vf

0.58

0.58+0.42 (13)

1.8

= 0.56

= 0.50

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 2 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:

9781118170519

Author:

Norman S. Nise

Publisher:

WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:

9781337093347

Author:

Barry J. Goodno, James M. Gere

Publisher:

Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:

9781118807330

Author:

James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:

WILEY